Sulphur, sediment the main issues in IMO 2020 transition, survey finds

The transition to IMO 2020 compliant fuel oil (0.5% sulphur) has not been without problems, with sulphur content, sediment, and aluminium plus silicon being the main issues experienced, a recent survey found.

The transition to IMO 2020 compliant fuel oil (0.5% sulphur) has not been without problems, with sulphur content, sediment, and aluminium plus silicon being the main issues experienced, a recent survey found.

The Fuel Oil Quality and Safety Survey, launched in February by BIMCO, ICS, INTERCARGO and INTERTANKO, aimed to get a greater understanding of the quality of the new fuel oils and possible safety implications of the IMO 2020 sulphur cap.

The survey ran from 24 February until 6 May and was targeted at shore-based personnel: The three most frequent respondents were from technical departments (52.6%), operational functions, such as fleet and vessel management (21.9%), and bunker departments (8.3%). The dataset is based on 192 responses.

Among the key findings was that 14% of the respondents answered ‘no’ to all ten questions (Q2 to Q11) regarding off-spec and operational quality issues. This shows that some respondents had not experienced any problems at the time when responding to the survey.

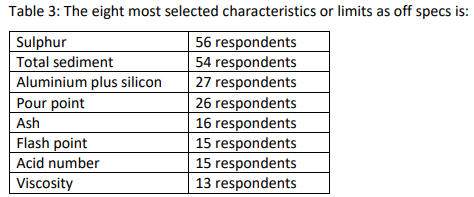

The eight most selected characteristics or limits in accordance with ISO 8217 as experienced being off specifications (off-spec):

- Sulphur

- Total sediment

- Aluminium plus silicon

- Pour point

- Ash

- Flash point

- Acid number

- Viscosity

Main findings

More specifically, 62% of the respondents have to some extent experienced increased sludge deposits in the fuel oil system including increased sludge discharge from the ship’s separators.

- 32% of the respondents answered that they had experienced wax appearance in the fuel oil system e.g. in fuel oil tanks, filters etc.

- 31% of the respondents answered that they had experienced operational issues caused by increased wear and tear of cylinder liners, piston rings or other components, assessed to be due to increased amounts of catalytic fines (cat fines) in the fuel oil.

- 22% of the respondents answered that fuel oil had been de-bunkered as a consequence of fuel oil properties.

- 21% of the respondents answered that they had experienced problems with fuel injection, poor ignition or incomplete combustion of the fuel.

- 18% of the respondents answered that they had experienced fuel oil pumps seizures.

- 10% of the respondents answered that they had experienced loss of propulsion and/or black out as a consequence of fuel oil properties.

"The answers and comments provided by respondents suggest that the transition to IMO 2020 compliant fuel oil (0.5% sulphur) has not been without problems. As fuel oil properties are fluctuating, quality and safety problems will continue to be a challenge for the global shipping industry."

Survey results

Q1 – Standards used for the specifications of the latest compliant fuel oil ordered and delivered to one of your ships

The three most common answers are:

- ISO 8217:2010 81 respondents 42% of 192 respondents

- ISO 8217:2017 49 respondents 25% of 192 respondents

- ISO 8217:2005 35 respondents 18% of 192 respondents

It is observed that 3 respondents answered that the standard used for the specifications of bunker depended on the contract with the charter. Furthermore, 3 respondents answered that the availability varies depending on the

geographical area.

Q2 – Fuel oil analysis results indicated off specifications

- 55% of the respondents answered “yes” to whether any of the fuel oil analysis results had indicated off specifications (off-spec).

- 45% of the respondents answered “no” to whether any of the fuel oil analysis results had indicated off specifications (off-spec).

"The 56 respondents (equivalent to 29.2% of all respondents) does not mean that 29.2% of all ships are or have been non-compliant with the statutory MARPOL sulphur content requirement. It simply means that based on the ships, for which they are responsible, 56 respondents have experienced that one or more fuel oil analysis result(s) had indicated the sulphur content may be non-compliant."

Q3 – Flash point

- 10% of the respondents answered “yes” to whether any of the fuel oil analysis results had indicated a flash point temperature below 60°C.

- 88% of the respondents answered “no” to whether any of the fuel oil analysis results had indicated a flash point temperature below 60°C.

- 2% of the respondents answered that they did not know whether any of the fuel oil analysis results had indicated a flash point temperature below 60°C.

- 15 respondents selected ’flash point’ as one of the characteristics or limits that had been off specifications in question number two (Q2). The same 15 respondents also answered ’yes’ to the question (Q3) whether any of the fuel oil analysis results had indicated a flash point temperature below 60°C. However, a total of 20 respondents answered ’yes’ to the question (Q3) whether any of the fuel oil analysis results had indicated a flash point temperature below 60°C.

Q4 & Q5 – Sludge deposits and discharge

Q4 – Have you observed increased sludge deposits in fuel oil tanks, and/or clogging fuel pipes, separators, preheaters, fuel oil transfer pump suction filters etc?

- 53% of the respondents answered “yes” to observing increased sludge deposits in fuel oil tanks, and/or clogging fuel pipes, separators, preheaters, fuel oil transfer pump suction filters etc.

- 47% of the respondents answered “no” to observing increased sludge deposits in fuel oil tanks, and/or clogging fuel pipes, separators, preheaters, fuel oil transfer pump suction filters etc.

Q5 – Have you experienced increased sludge discharge from the ship’s separators?

- 55% of the respondents answered “yes” to experiencing increased sludge discharge from the ship’s separators.

- 45% of the respondents answered “no” to experiencing increased sludge discharge from the ship’s separators.

Q6 – Fuel oil pumps seizures

- 18% of the respondents answered “yes” to experiencing fuel oil pumps seizures. 82% of the respondents answered “no” to experiencing fuel oil pumps seizures.

Q7 – Problems with fuel injection, poor ignition or incomplete combustion

- 21% of the respondents answered “yes” to experiencing problems with fuel injection, poor ignition or incomplete combustion of the fuel.

- 79% of the respondents answered “no” to experiencing problems with fuel injection, poor ignition or incomplete combustion of the fuel.

Q8 – Wax appearance

- 32% of the respondents answered “yes” to experiencing wax appearance in the fuel oil system e.g. fuel oil tanks, filters etc.

- 68% of the respondents answered “no” to experiencing wax appearance in the fuel oil system e.g. fuel oil tanks, filters etc.

Q9 – Wear and tear due to catalytic fines

- 31% of the respondents answered “yes” to experiencing operational issues caused by increased wear and tear of cylinder liners, piston rings or other components, assessed to be due to increased amounts of catalytic fines (cat fines) in the fuel oil.

- 57% of the respondents answered “no” to experiencing operational issues caused by increased wear and tear of cylinder liners, piston rings or other components, assessed to be due to increased amounts of catalytic fines (cat fines) in the fuel oil.

- 12% of the respondents answered “I don’t know” to experiencing operational issues caused by increased wear and tear of cylinder liners, piston rings or other components, assessed to be due to increased amounts of catalytic fines (cat fines) in the fuel oil.

Q10 – Loss of propulsion and/or black out

- 10% of the respondents answered “yes” to experiencing loss of propulsion and/or black out as a consequence of fuel oil properties.

- 89% of the respondents answered “no” to experiencing loss of propulsion and/or black out

as a consequence of fuel oil properties. - 1% of the respondents answered “I don’t know” to experiencing loss of propulsion and/or black out as a consequence of fuel oil properties.

Q11 – De-bunkering

- 22% of the respondents answered “yes” to fuel oil being de-bunkered as a consequence of fuel oil properties.

- 77% of the respondents answered “no” to fuel oil being de-bunkered as a consequence of fuel oil properties.

- 1% of the respondents answered “I don’t know” to fuel oil being de-bunkered as a consequence of fuel oil properties.

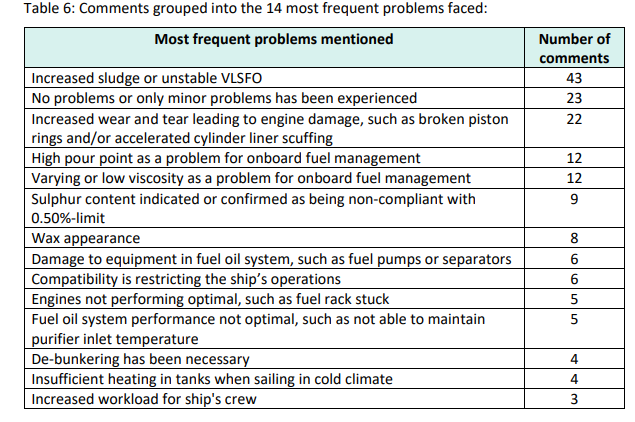

Q12 – Descriptions of any other problems faced by your ships caused by fuel oil properties since changing over to compliant fuel oil and any mitigating actions taken

124 comments were received concerning problems faced due to fuel oil properties since changing over to compliant fuel oil.

Q13 – Comments received regarding the procurement, availability, or bunkering of VLSFO or ULSFO

73 comments were received concerning procurement, availability, or bunkering of VLSFO or ULSFO.

![AIRBUS A380 [MORE THAN 600 PASSENGER’S CAPACITY PLANE]](https://cdn.tinn.ir/thumbnail/4jCp4EQvCU0b/IjHVrSYQrIAqIzXuTzADR7qLYX4idQT4nfq__26E5SCUPLMqfhWkWajvuO9Wfq1ql1TjV4dhkrHliNQU82kMpo2NNftT_NGEwHc9KXtN_rk731bmifa2IQ,,/airbus-a380-structure1.jpg)

Send Comment